Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

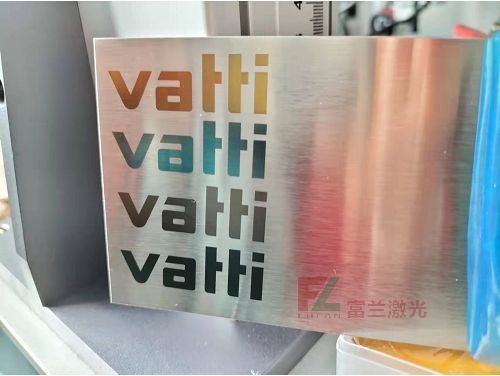

Stainless steel laser marking white and black is common, but it is relatively rare to print color. At present, other materials cannot be colored, only stainless steel can be colored. Why?

First of all, please follow Foshan Fulan Laser to understand the principle of the laser marking machine: the laser generates high temperature through laser focusing to evaporate the surface material on the material surface to expose the deep material, or through the chemical and physical changes of the surface material caused by light energy to display the mark information. Next, let's learn about the principle of color laser marking on stainless steel.

There are three principles of stainless steel color development:

1. It is to generate colored oxides: under the action of the laser heat source, the stainless steel material generates colored oxides on the surface, or a colorless and transparent oxide film is formed, which presents various colors due to the thin film interference effect of light. The oxidized product of the metal element itself will also show color;

2. Under the action of chemical, electrochemical or laser, a very thin colorless and transparent oxide film is formed on the surface of stainless steel, and the oxide film produces interference effect, which can show color on the surface;

3. It is a mixed state of colored oxide and oxide film at the same time.

Under the action of the laser, the surface of the stainless steel produces a laser thermal effect, and through the laser thermal effect, it is concluded that the laser energy density is proportional to the film thickness. As the laser energy increases, the color of the stainless steel surface shows a regular change: yellow, red, blue, green until it gradually darkens. Therefore, by controlling the laser energy density, the desired color can be printed on stainless steel products.

Compared with ink deposition technology and color powder film technology to display color, laser color marking technology has great advantages. It has color persistence and indelibility, simple operation, can mark any pattern and text, no consumables, environmental protection and no pollution, and a high degree of automation. The use of laser marking color can not only greatly increase the added value of metal products, but also enhance the competitiveness of metal products.