Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

Even the best and the most advanced equipment will cause poor processing results due to certain factors, and laser welding machines are no exception. Next, Fulan Laser will briefly talk about the main reasons that lead to unsatisfactory laser welding results.

1. Equipment:

This is one of the main reasons. If you want high-precision welding with low-configuration equipment, it is definitely impossible; if the corresponding material does not use the corresponding equipment, the welding effect is definitely not good (such as: Copper, aluminum, silver and other high-reflective materials are not welded with pulsed YAG laser welding machines, but welding machines with other types of lasers will definitely cause pores and cracks).

2. Material:

a. Absorption rate of the material: The compatibility of the laser beam and the absorption of the material depends on some important properties of the material, such as absorptivity, reflectivity, thermal conductivity, etc. The most important of which is the absorption rate. Some materials are particularly good for laser absorption, while some materials are very poor or even do not absorb.

b. Material uniformity: refers to the state where one or several characteristics of a substance have the same composition or structure. The uniformity of materials directly affects the effective use of materials. For example: when aluminum alloy materials are welded, the distribution of alloy elements is uneven, and welding defects such as blast holes, undercuts, and depressions are prone to occur.

3. Fixture:

The fixture is mainly used for accurately positioning and reliably clamping the workpiece to be welded, which is convenient to ensure the accuracy of the welding structure, and effectively prevents and reduces welding deformation. The quality of the fixture will directly affect the quality of welding.

4. Workbench:

The workbench will directly affect the processing efficiency and the welding effect. The laser welding machine produced by Foshan Fulan Laser has flexible placement and can be configured with different workbenches for welding processing according to the needs of different products.

5. The parameters of the laser welding machine:

The welding process parameters mainly include laser output power, welding speed, laser waveform, pulse frequency, defocus amount and shielding gas.

a. Output power stability: The better the laser output power stability, the better the welding consistency.

b. Welding speed: the higher the welding speed, the shallower the penetration. The molten pool at low speed is large and wide, and it is prone to collapse. During high-speed welding, the liquid metal in the center of the weld is too late to redistribute, so it solidifies on both sides of the weld, forming an uneven weld. Therefore, Foshan Fulan Laser recommends that you use high-speed welding when welding thin plates or materials with better weldability; low speed for thick plates and difficult-to-weld materials.

c. Laser waveform: The laser waveform mainly includes the pulse waveform commonly used by pulse lasers and the seam welding waveform during continuous welding. For welding copper, aluminum, gold, and silver highly reflective materials, in order to break through the barrier of high reflectivity, trapezoidal laser waveforms can be used; for ferrous metals such as iron and nickel, where the surface reflectivity is low, rectangular waves or slow attenuation waveforms should be used .

d. Pulse frequency: The pulse frequency, spot size and welding speed are matched with each other to achieve the required overlap rate. Generally speaking, the greater the overlap rate, the smoother the weld, but the welding speed also decreases accordingly. When the laser pulse frequency exceeds a certain value, the overlap rate is too large, exceeding the welding limit of the material, and it is easy to weld through or weld slag.

e. Defocus: There are two defocus methods, positive defocus and negative defocus. If the focal plane is above the workpiece, it is a positive defocus, otherwise it is a negative defocus. When the defocus is negative, the power density inside the material is higher than that on the surface, and it is easy to form stronger melting and vaporization, so that the light energy is transmitted to the deeper part of the material. Therefore, in practical applications, when the penetration depth is required to be large, negative defocusing is used; when welding thin materials, positive defocusing is appropriate.

f. Pulse width: This is mainly for pulse laser laser welding machine. Pulse width is one of the important parameters of pulse laser welding machine. It is not only an important parameter different from material removal and material melting, but also determines the cost and volume of processing equipment key parameter. The longer the pulse width, the larger the diameter of the solder joint, and the deeper the penetration at the same working distance.

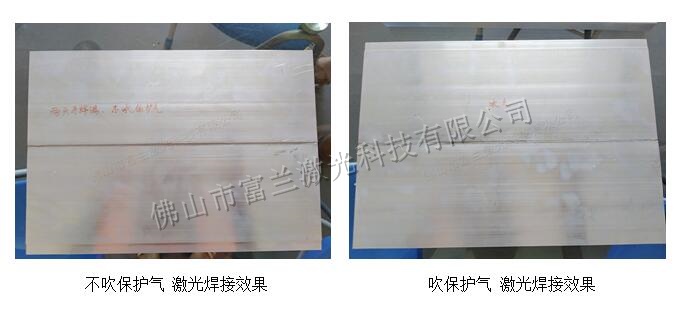

6. Auxiliary gas:

The laser welding process uses inert gas to protect the molten pool, which can make the welding place more smooth and beautiful without yellowing. Generally, nitrogen, argon, and helium are used. Helium has the highest cost, but its anti-oxidation effect is good, and its ionization degree is small, so it is not easy to form plasma. Argon has a good anti-oxidation effect, but it is easy to ionize; nitrogen has the lowest cost and is generally used for welding stainless steel.

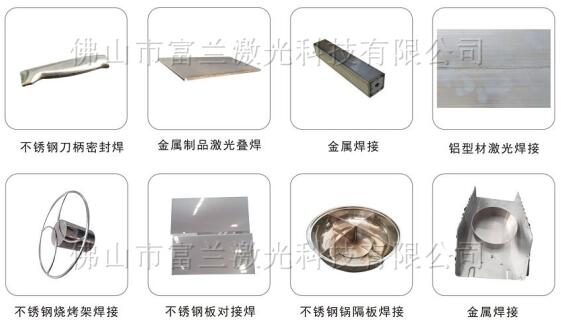

Most of the laser welding machines produced by Foshan Fulan Laser Technology Co., Ltd. are customized. Because each customer needs to weld the product material or shape and requirements are different, Fulan Laser helps customers design the shape and performance of the machine according to the actual situation of the customer, and can customize special automatic tooling fixtures. It can also provide customers with a complete set of laser processing equipment, laser automation integration, and various automated production lines.