Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

The so-called ultraviolet laser marking machine, as the name implies, is that the light source it uses is an ultraviolet laser. The laser wavelength is 355nm (so, people call it 355nm marking machine), all cold light source (so, people also call it cold light marking machine), with stable power, high integration, small size, long life, beam quality Excellent and high stability. Mainly used in the high-end market of ultra-fine processing.

Principle: The principle of laser marking machine is similar to that of other light sources. It uses laser beam to make permanent marks on the surface of various materials. The effect of marking is to directly break the molecular chain of the substance through the short-wave laser (different from the evaporation of the surface substance produced by the long-wave laser to expose the deep substance), thereby displaying the desired marking pattern and text.

Ultraviolet laser marking belongs to cold processing. The processing process is called "photoetching" effect. "Cold processing" has high-energy (ultraviolet) photons, which can break the chemical bonds in materials (especially organic materials) or the surrounding medium. The material undergoes non-thermal process destruction. There is no heating or thermal deformation on the inner layer and nearby areas of the processed surface.

Ultraviolet laser marking machine is regarded as a relatively high-end marking machine equipment on the market, and its relative price is more expensive than other ones. Because of its very small focus spot and small processing heat affected zone, it can be used for ultra-fine marking and special materials. Marking. This machine is the first choice if the marking effect is high.

There are 3 watts, 5 watts, and 8 watts that are used more in the market. The higher the power, the higher the price.

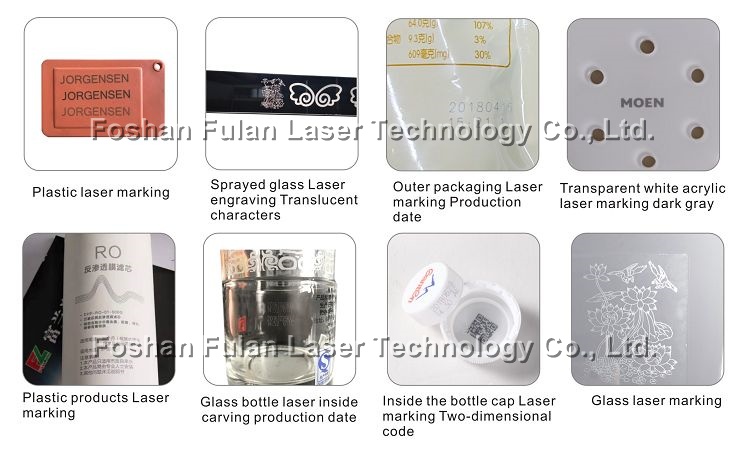

Most of the UV equipment below 5 watts is used for precision marking, such as: precision marking flexible PCB boards, glass, polymer plastics, plastic parts with UV oil, high-demand transparent keys, and materials that are particularly sensitive to light. And so on; cutting FPC boards, silicon wafers, glass and other thin slices; peeling off the coating on the surface of electroplated parts or sprayed parts; scribing of various materials, blind groove processing, etc.

Equipment above 5 watts is mainly used in high-end precision cutting and precision drilling.

The UV laser marking machine produced by Foshan Fulan Laser Technology Co., Ltd. has three models: FL-E2-3, FL-E2-5 and FL-E2-8. They all use imported laser light sources with high beam quality. The small focus spot makes the marking finer and higher definition; and the heat-affected area is small, no thermal effect is generated, and the deformation and damage or scorching of the processed materials are avoided; the applicable materials are particularly wide, which solves the problem of marking many materials with fiber laser Insufficient detail, poor effect, etc.; fast marking speed and high efficiency. It can be configured on the assembly line to realize the function of online flying marking.