Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

Some users who use laser marking machines may encounter a problem: "When marking some plastic products, either the marking fails, the marking is not clear, or the plastic surface will have bubbles after marking. ". So how to solve these problems?

The first method:

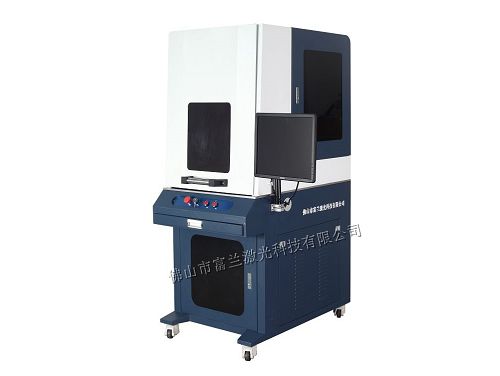

Using UV laser marking machine, this equipment is a relatively high-end marking machine on the market, and its relative price is also more expensive than others. Because of its very small focus spot and small processing heat-affected zone, it can be used for ultra-fine marking and special material marking. It is mainly used in the high-end market of ultra-fine processing, 3C industry marking, electronic components, electrical housing marking, food, medicine and other polymer materials marking, as well as marking of materials that are particularly sensitive to light; therefore, plastic marking UV laser marking machine is the first choice.

The second method:

Add laser powder to raw materials (also called laser powder, laser additive, laser marking powder)

The main function of the laser powder is to absorb laser energy, convert the laser beam into heat energy, produce heat, carbonization, evaporation and chemical reactions caused by the discoloration of the additives themselves, thereby forming a marking pattern on the surface of the product!

It is suitable for various engineering plastics, modified plastics and coatings (inks, paints, unsaturated resins) and other materials.

PS: Regarding the phenomenon of blistering in laser marking of some plastic materials, the main source is the workpiece. If the marking is performed after protective oil (that is, sealing oil), blistering is unavoidable.