Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

The so-called aluminum profile refers to products made of aluminum and other alloying elements. The main metal element is aluminum, plus some alloying elements to improve the performance of aluminum. Aluminum profile products have the advantages of high strength, light weight, corrosion resistance, good decoration and long service life.

Aluminum profiles are widely used in all walks of life, most of the aluminum profile products in the manufacturing process, the welding process is indispensable. Because traditional welding methods have many disadvantages and hazards, and in recent years, laser welding technology has matured, and the price has become more and more affordable, so most companies have adopted laser welding machines for welding processing.

Laser welding uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation diffuses into the material through heat conduction, and the material is melted to form a specific molten pool. It can realize spot welding, butt welding, stitch welding, sealing welding, tailor welding and other welding. Below, Foshan Fulan Laser mainly talks about tailor welding (double-sided laser tailor welding of aluminum profile).

Laser tailor welding is to use laser energy to join and weld several metal materials of different materials or different specifications or different coatings into a whole plate, profile, etc.

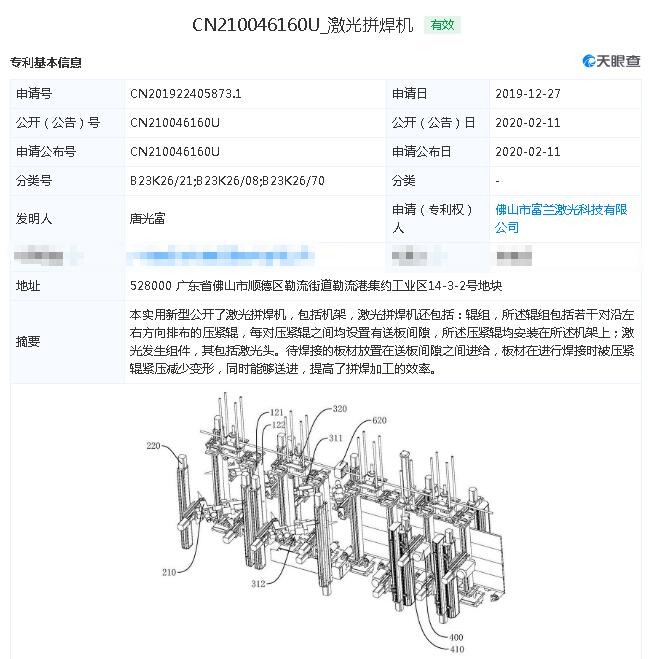

The existing laser welding machine on the market, in order to resist the deformation of the plate caused by heating during the welding process, the usual method is to use the clamping device to press and fix the plate when the plate is welded. For welding, not only the welding efficiency is limited, but the defect rate is also high. Therefore, according to customer needs, Foshan Fulan Laser Technology Co., Ltd. independently researched and produced a special equipment for double-sided welding-laser tailored welding machine. This double-sided laser tailor-made welding machine can better dissipate the heat during welding, which improves the efficiency of laser tailor-made welding.

The use of laser welding machine welding processing has high power density, high speed, low welding heat input, small welding heat affected zone, small welding deformation, flat weld without air holes, precise control, high positioning accuracy, simple operation (no need for professional welding Personnel, only one or two employees are required to change materials), low operating cost, automatic welding, wide application of materials, and the ability to complete any track welding at one time, making it particularly popular in the welding field.