Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

Plastic (high molecular polymer) is a high molecular compound made from monomers as raw materials through addition polymerization or condensation polymerization. It is composed of synthetic resin and fillers, plasticizers, stabilizers, lubricants, colorants and other additives.

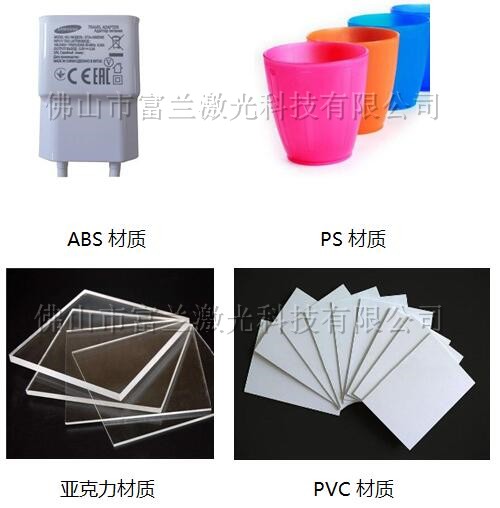

Plastics can be roughly divided into: PE (polyethylene), PP (polypropylene), PET (polyethylene terephthalate), AS/SAN (styrene-acrylonitrile copolymer), ABS (acrylonitrile-butylene Diene-styrene copolymer), PVC (polyvinyl chloride), PMMA (polymethacrylate, which is often referred to as acrylic or plexiglass), PET material (polyethylene terephthalate, we commonly Mineral water bottles and carbonated beverage bottles are made of this material), PA (polyamide, commonly known as: nylon), PC (polycarbonate), PS (polystyrene), etc.

Different types of plastics have different absorption rates of laser energy. Some plastics are easy to absorb laser energy and are easy to mark; while some plastics do not absorb laser energy, high-quality marks cannot be made, or even cannot be marked; some plastics have bubbles on the surface during laser marking.

Why does this happen? Because the absorption rate of laser energy is a function of wavelength, different plastics will get different quality marks under the same laser intensity. So, how does the laser marking machine make high-quality (clear and beautiful) marks on plastic?

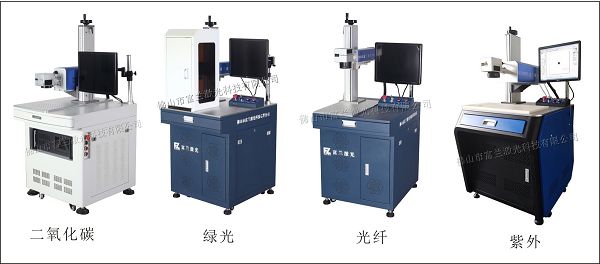

1. According to the plastic material and the effect to be marked, select the appropriate laser marking machine model:

The fiber optic machines, green light machines, UV machines, and carbon dioxide machines produced by Foshan Fulan Laser Technology Co., Ltd. can mark plastics.

Because different types of lasers emit different wavelengths and different penetrating capabilities; and the adaptability of different lasers has an impact on the marking quality and marking speed. Therefore, plastics of different materials and plastics of the same material and different purity are different. The type of laser marking machine used will be different, and each customer has different marking requirements. Therefore, which laser marking machine is the most suitable for your product, you need to make a sample before you can determine. Before customers purchase laser equipment, Foshan Fulan Laser will make free samples for customers, and select suitable laser marking machines for customers.

2. Add laser marking powder

Laser marking powder, it is mainly used to mark PP, PE, PBT, PVC, ABS, TPU, PS, TPE, TPV, TPR, PET, PC, POM, SEBS, PEI and other plastic materials when laser engraving It is not clear or can not be marked. A special substance must be added, which can make the plastic marking clearer and will not fade due to physical or chemical factors.

The laser marking machine produced by Foshan Fulan Laser Technology Co., Ltd. has a complete range of styles and models. No matter what material you are using for marking, there is always a product of Fulan Laser for you.